Contents

1. Don’t Settle for Retail Rates

Negotiate shipping rates. FedEx, UPS, and DHL provide negotiated rates. Pit them against each other and have at least two negotiated rate carriers.

If you lack shipping volume, or if you’re a new business, you can provide projected shipping volume to obtain negotiated prices.

Don’t forget to also negotiate on other factors such as pickup fees, residential delivery surcharges, additional fuel costs, and insurance. Carriers like UPS can add many surcharges to your bill.

Example: This shipper gets 7lb 16x12x12″ coast to coast packages at a $15.73 and 12x8x8″ packages at $11.31, which is significantly cheaper than the already-discounted rates provided by shipping platforms. How is this done? By pitting UPS and FedEx against each other and negotiating rates.

USPS usually does not provide price breaks until at least 1 million dollars in shipping spend. But you can get discounted USPS rates through platforms like Pirate Ship, EasyShip, or ShipStation.

Use Partnered Rates with Shipping Platforms

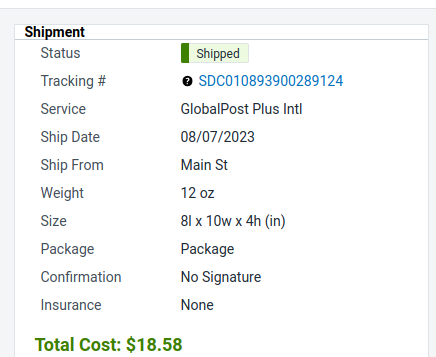

Example: GlobalPost with ShipStation

For our retail business, we negotiated with DHL for international rates which took about two weeks. Meanwhile we’re receiving international orders and have to ship. ShipStation’s GlobalPost rates were cheaper than DHL’s negotiated rates. Here’s a 12 oz shipment to QLD Australia for $18.58

2. Use Poly Mailers

Or a recycled, eco-friendly alternative. You can ditch boxes and go with poly or padded mailers to reduce shipping weight and packaging material cost. Soft-body mailers are a fraction of the cost compared to most boxes.

Consider secondary packaging for fragile products: If your product is fragile, compare the cost of rigid secondary packaging against the cost of carboard shipping boxes.

Secondary product packaging can provide a better user experience (instructions and branding) and can be cheaper than shipping boxes, depending on the material.

Reduced size: Flexible mailers conform to the shape of the product, which reduces negative space, further reducing shipping cost.

Reduced weight: Made of polyethylene film, poly mailers are much lighter than their carboard box counterparts.

3. Rethink Your Product Packaging

Primary packaging is the last line of defense between your product and the environment. For chips, it’s the foil bag. For wine, it’s the bottle.

Can your product’s primary packaging be lighter or flexible? Consider boxed wine that uses a bag and box instead of a bottle. Or supplement and food products sold in pouches instead of heavy plastic tubs.

There’s a science dedicated to this called packaging engineering.

If you’re a small business without in-house engineers, there are companies who provide package engineering services. But ask your supplier first since they may offer different packaging options without additional costs.

4. Use Free Carrier-Provided Shipping Supplies

USPS provides free flat rate packaging for Priority Mail and Priority Mail Express.

UPS and FedEx offer free shipping boxes, but you can only use them for the more expensive (non-Ground) options.

UPS provides free shipping labels. FedEx also provides some free labels, but they’re strict on ensuring your shipped volume matches your labels ordered. Either way, these free labels should only be used for UPS or FedEx shipments respectively.

5. Encourage Larger Orders

Set a free shipping threshold. Amazon sets their threshold at $25 for non-Prime users. Your threshold might be higher or lower depending on your average shipping cost and profit per item.

Offer discounts for larger orders. Create product bundles or sets.

Quantity discounts, also called quantity breaks or tiered discounts, kick in when customers order multiples of the same item. This is ideal for business customers and is something Amazon provides for its Amazon Business users.

6. Compare 3PL Prices

Compare your in-house shipping cost per pick/item to 3PL (third-party logistics) provider prices.

Get your average cost per item for:

- labor

- shipping materials

- shipping price

- Other factors such as pickup service fees, setup time for fulfillment, etc.

3PL providers, especially Amazon, have much lower shipping prices than you have access to due to their volume.

7. Bootstrap a (Micro) Fulfillment Network

If 3PL costs are too high, look for other sellers in different states, preferably at least several states away.

Micro-fulfillment, micrologistics, whatever the logistics lingo used, you’re basically sending product to small fulfillment centers located closer to your customers. This is done by routing your orders to the fulfillment center closest to the customer like Amazon does.

Figure out an order routing solution. Some shipping platforms can route orders to different fulfillment centers (warehouses) based on rules. Shopify includes order routing.

Exchange inventory with the other seller(s). Then agree on compensation when one person picks more items than the other.